项目名称: 高强度螺栓过火冷却后力学性能试验研究

Mechanical properties of high-strength bolts after fire

项目来源:国家自然科学基金项目

试验时间:2010年6月

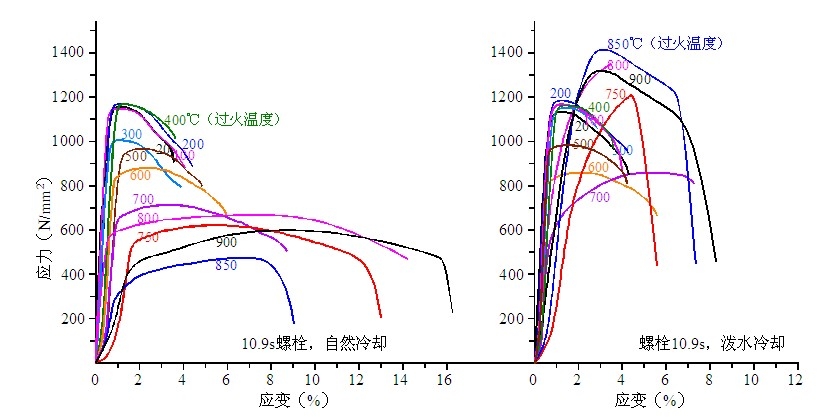

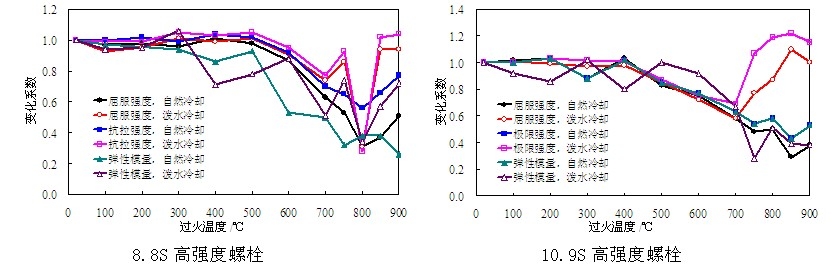

项目简介:高强度螺栓连接是钢结构最常用的连接方式之一,其火灾后受力性能对整个结构灾后承载安全至关重要。通过对常用的8.8S和10.9S高强度螺栓进行高温过火冷却后力学性能试验研究,得到了过火温度对应力―应变关系曲线、屈服强度、抗拉强度和弹性模量的影响规律。试验包括自然冷却、泼水冷却两种冷却方式。研究结果表明:当过火温度超过400℃时,过火与冷却作用对高强度螺栓的力学性能将产生较大的影响;当过火温度超过700℃时,冷却方式对高强度螺栓的力学性能影响有较大的差别,在自然冷却条件下,延性不断加大,强度有略微回升,但幅度不明显;在泼水冷却的情况下,应力―应变曲线呈现明显脆性,塑性平台消失,强度大幅度回升,在过火温度超过800℃后10.9S高强度螺栓的强度甚至比未受火时提高约20%。

High-strength bolts which are widely used in steel structural connections are more temperature-sensitive than hot finished steel. To obtain the mechanical properties of high-strength bolts after fire including stress-strain curves, strength and elasticity modulus, a series of experiments on 8.8S bolts and 10.9S bolts were carried out in this study. In order to simulate the real situations in event of fire, both natural cooling and water cooling were employed in the tests. The test results show that heating and cooling have a great effect on the mechanical properties of high-strength bolts after fire when the temperature of high-strength bolts attained is above 400℃. And the effect of natural cooling is very different from that of water cooling when attained temperature is above 700℃. After natural cooling, the stress-strain curves become softer and more ductile, and the strength is regained slightly. After water cooling, the ductility reduces significantly whereas the strength is regained to a great extent. For 10.9S high-strength bolts subjected to water cooling the post-fire strength even exceeds the normal strength approximately 20% when the attained temperature is in excess of 800℃.

关 键 词: 高强度螺栓;自然冷却;泼水冷却;受火试验;受火后静力试验;力学性能

Keywords: high-strength bolt; natural cooling; water cooling; fire test; static test after fire; mechanical properties

----------------------------------------------------------------------------------------------------------------------------------------------------

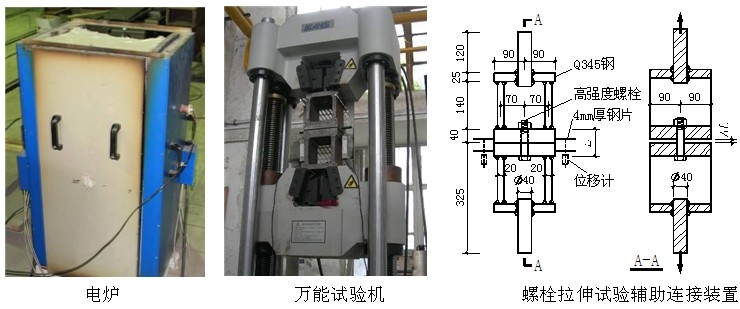

试验装置:电炉、万能试验机

试验结果:主要试验结果、结论

(1)应力―应变―过火温度的关系曲线

(2)强度降低系数

(3)试件破坏照片